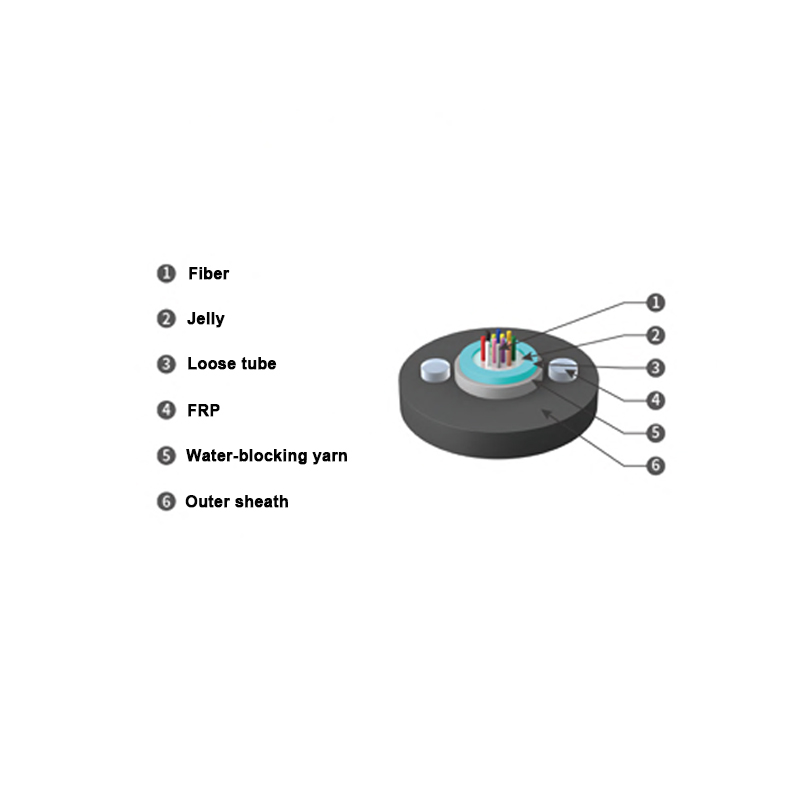

The structure of flat fiber optic cable is to sheath single-mode or multi-mode optical fiber into a loose tube made of high modulus plastic, and the tube is filled with water blocking compound. The loose tube is covered with double-sided plastic coated (wrinkle) copper tape longitudinally.

The water blocking tape between the steel tape and the loose tube ensures the compactness and longitudinal water blocking of the optical cable. Two non-metallic FRP reinforced rear guards are placed on both sides and finally set into a flat fiber optic cable. As a professional fiber optic products supplier, TUOLIMA can customize the optical cable according to your requirements.

Item | Technology parameter | |

Code | 2019-HZSFT-0008 | 2019-HZSFT-0009 |

Cable type | GYFXBY-2~24B6 | GYFXBY-2~24B1 |

Fiber type | 9/125 (HT G657A2) | 9/125 (HT G652D) |

Fiber color | Blue, orange, green, brown, gray, white, red, black, yellow, violet, pink, aqua | |

Filler | Jelly | |

Inner jacket color | Natural | |

Inner jacket material | PBT | |

Inner jacket diameter mm | 3.0±0.1 | |

Strength member | FRP &water-blocking yarn | |

Strength member diameter mm | 1.6 | |

Outer sheath color | Black | |

Outer sheath material | PE | |

Outer sheath dimension mm | 7.7(±0.3)×4.3(±0.3) | |

Cable weight Kg/km | Approx. 34.9 | |

Min. bending radius mm | 20D (Static) 40D (Dynamic) | |

Attenuation dB/km | ≦ 0.4 at 1310nm, ≦ 0.3 at 1550nm | |

Short tensile strength N | 800 | |

Short crush resistance N/100mm | 2200 | |

Operation temperature ℃ | -20~+70 | |

Note: the product is in accord with the instruction of EU RoHS

The water-blocking tape is longitudinally wrapped to prevent the longitudinal water seepage of the optical cable and fiber optic cable clamps

Two parallel steel wires ensure the tensile strength of the optical cable

PE sheath has good resistance to ultraviolet radiation and environmental stress cracking resistance

Small diameter, light weight, easy to lay

Packing material: Non-returnable wooden drum.

Both ends of cable are securely fastened to drum and sealed with a shrinkable cap to prevent ingress of moisture.

Cable printing: The sequential number of the outdoor armored fiber optic cable length shall be marked on the outer sheath of the cable at an interval of 1meter ± 1%.

The following information shall be marked on the outer sheath of the cable at an interval of about 1 meter.

Cable type and number of optical fiber

Manufacturer name

Month and Year of Manufacture

Cable length

Drum marking: Each side of every wooden drum shall be permanently marked in a minimum of 2.5~3 cm high lettering with following:

Manufacture name and logo

Cable length

Cable type and number of fibers

Roll way

Gross and net weight

Related Products

IP68 Fiber Optic Splice Closures — Designed to provide secure and reliable protection for fiber optic joints

Aug 02-2024

Enhancing Campus Connectivity: GJYXCH Fiber Optic Cable in Educational Networks

Jan 09-2024

Elevating Urban Infrastructure: GJYXCH Fiber Optic Cable in Smart City Networks

Jan 07-2024