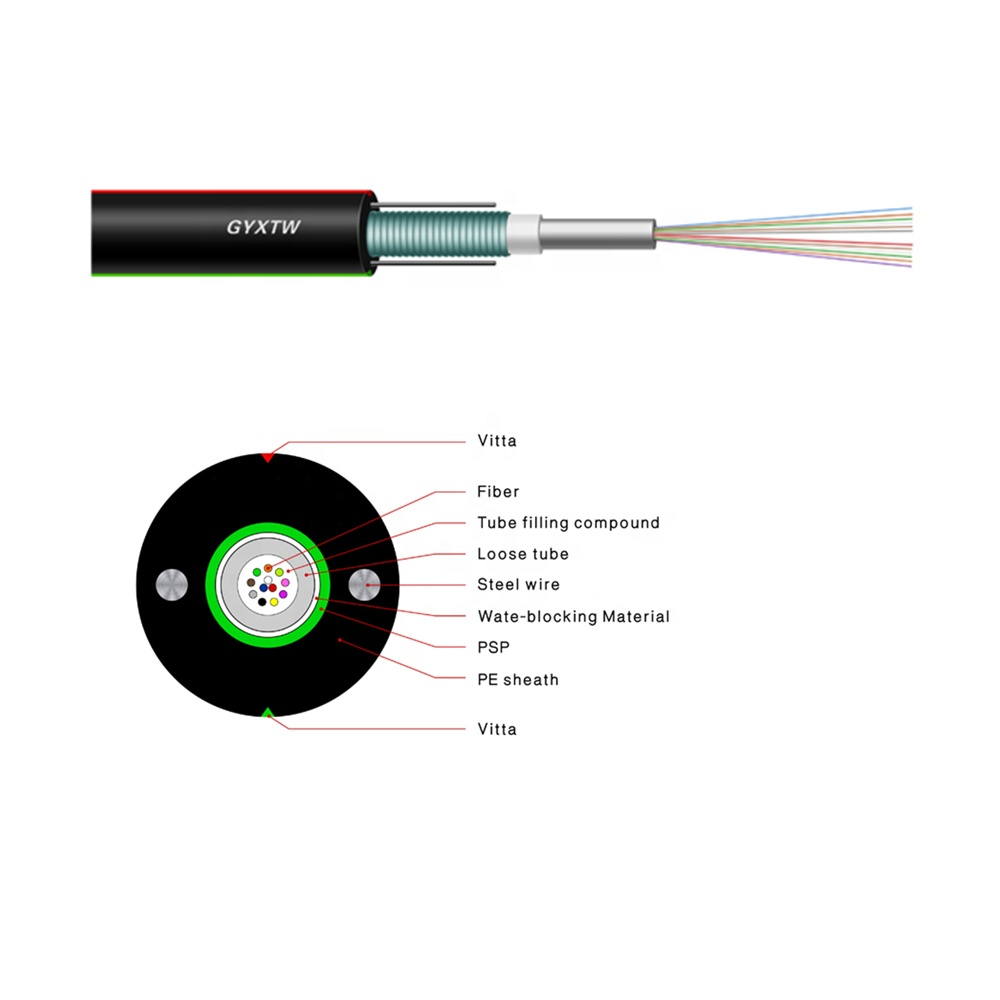

Fiber Optic GYXTW cable is to sheath 250μm optical fiber into a loose tube which is filled with waterproof compound. Water blocking material is added between the steel tape and the loose tube to ensure the compactness and longitudinal water blocking of the optical cable.The gyxtw fiber optic cable is widely used for long-distance communication and inter-office communication which is thus, popularly applied world widely. Among those cables, 8 core GYXTW Fiber Optic Cable is the most popular.

As a fiber optic products supplier, we have been manufacturing GYXTW Fiber Optic Cable for over 10 years with ISO, UL, RoHS, REACH certificates. Reliable quality has won its popularity across five continents and the spread is growing. If you are looking for high-quality Fiber Optic GYXTW cable, we can meet your needs. With years of experience in Fiber Optic GYXTW cable manufacturing, TUOLIMA is your ideal and reliable Fiber Optic GYXTW cable supplier/manifacturer. Welcome to consult.

Excellent water blocking layer, with good impermeability

The outer sheath of steel tape is bonded and metal reinforced leading to excellent tension performance

The central design of the beam tube minimizes the impact on the optical fiber

Small outer diameter, lightweight, convenient construction

Stable fiber excess length control

After the cable is formed, the additional attenuation of the GYXTW fiber optic cable is almost zero, and the dispersion value does not change

Adapt to most environment

Structure | Unit | Parameter | ||

Fiber count | Fibers | 2~12 | 24 | |

Loose tube Diameter | mm | Nom. Ф2.5 | Nom. Ф3.0 | |

Strength Member | mm | Ф0.9*2 | ||

Armor | Material | -- | steel tape | |

Cable diameter | mm | Nom. Ф7.3 | Nom. Ф7.8 | |

Outer Sheath | Thickness | mm | Min.0.8 mm | |

Cable weight | Kg/km | Approx.58 | Approx.66 | |

Bending Radius | Dynamic | mm | ≥20D(D:Cable Diameter) | |

Static | mm | ≥10D(D:Cable Diameter) | ||

Operating Temperature | ℃ | -40 --- +60 | ||

The outdoor fiber optic cable is wound on a non-returnable wooden drum. Both ends of the cable are securely fastened to the drum and sealed with a shrinkable cap to prevent ingress of moisture. The following information shall be marked on the outer sheath of the cable at an interval of about 1 meter.

Cable type and number of optical fiber

Manufacturer name

Month and Year of Manufacture

Cable length

The sequential number of the cable length shall be marked on the outer sheath of the cable at an interval of 1meter ± 1%.

Drum marking, Each side of every wooden drum shall be permanently marked in a minimum of 2.5~3 cm high lettering with following:

Manufacture name and logo

Cable length

Cable type and number of fibers

Roll way

Gross and net weight

Related Products

IP68 Fiber Optic Splice Closures — Designed to provide secure and reliable protection for fiber optic joints

Aug 02-2024

Enhancing Campus Connectivity: GJYXCH Fiber Optic Cable in Educational Networks

Jan 09-2024

Elevating Urban Infrastructure: GJYXCH Fiber Optic Cable in Smart City Networks

Jan 07-2024